Infrastructure & Production Facilities

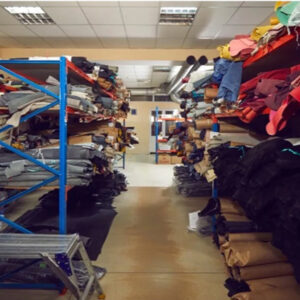

Our factory is based in ILPA (Indian Leather Products Association) Leather goods park, Kolkata Leather Complex in West Bengal, India which is the government authorized industrial complex developed for manufacturing of leather and leather related products. Current factory space is around 40,000 sq ft with a new facility under production of more than 1,00,000 sq ft. Our facility has the perfect blend of technology and craftsmanship, besides following lean manufacturing techniques and quality controls necessary for mass quality production.

We have adopted Japanese quality management systems of Kaizen- where a team of employees from different areas works on a week-long project to improve a specific process and reduce waste and Poka-Yoke -mechanism or added step built into the process to alert the operator of a mistake that needs immediate corrective or preventive action.

Production Capacity

We have a production capacity of 40,000 small leather goods and 10,000 bags per month.

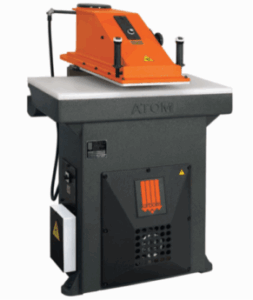

Great focus has been given to procuring efficient and best in class machines from all over the world such as:

Italian make- Camoga splitting machine, Omac auto creasing machine, Atom leather cutting machine, Omac Edge Inking machine

German make- Durkopp adler & Pfaff cylindrical bed stitching machine

Chinese make- Dashun Logo Stamping, Taking Skiving, Typical flat bed stitching machine etc

Japanese make- Juki sewing machine

Manufacturing Process Flow

Acting as an OEM and ODM for brands, the work flow chart is as following: